About EHC Knobs

The benefits for any medical product or medical component manufacturer can be highly favorable for current or ‘on-the-drafting board’ items. Further, the use of concurrent engineering methods adds to the value of outsourcing because the design engineer can play an integral role in the process.

Concurrent Engineering

The traditional, textbook definition of concurrent engineering is to develop products in parallel. The same concept and process can be applied to existing products once a company has approved the mission to review products for manufacturing outside the family. This business strategy can be applied to nearly each and every product. Following the steps of concurrent engineering practices can speed up the process and eliminate cumbersome and unnecessary tasks, while actually making it possible to do more with less.

According to Steve Sgammato, President at Electronic Hardware Corporation, a New York based contract manufacturer with operations in the US and China, “The way to reduce the time-line and streamline the process is to work within the concurrent engineering framework. It’s important that the internal engineer and the CM work together from the beginning. This enables a product, a series of products, or components to be identified, quickly evaluated, and the ones selected that will best benefit from being made elsewhere.”

The key area is for the design engineer to bring in the contract manufacturer (CM) as soon as possible and work together to evaluate products for outsourcing; then, create the plan to move the product overseas.

“The way to reduce the time-line and streamline the process is to work within the concurrent engineering framework. It’s important that the internal engineer and the CM work together from the beginning. This enables a product, a series of products, or components to be identified, quickly evaluated, and the ones selected that will best benefit from being made elsewhere.”

“The reason for this is simple,” he explained. “The design engineer knows the complexities of the product and the outsourcing person knows the capabilities of his overseas facilities. Work symbiotically . . . two different disciplines come together to form a very advantageous partnership.”

Our decision to outsource

In the late1990s Electronic Hardware Corporation (EHC) of Farmingdale, NY had reached a vital crossroads in its history. The manufacturer of injection-molded plastic knobs, dials, and pointers to the builders of consumer and commercial electronic devices was awash in spiraling costs. Its competitive ability was under fire. No matter what it did, internally EHC couldn't make a profit. "We were treading water at best," says Steven Sgammato, President of EHC. "We ran the gamut of incorporating new efficiencies and nothing worked. It all came down to labor and overhead since there's minimal automation in our processes."

As manufacturers struggle trying to deal with offshore competitors, many have chosen outsourcing to third world nations as their only answer to survival. EHC executives felt that developing direct relationships with assembly plants in China might be an effective way to lower manufacturing costs without the risky capital investment of building, then maintaining a plant. In the end, not only would this decision turn a $750,000 annual loss into a $1.2 million profit in three years, it would also reveal an entirely new and lucrative revenue stream.

How EHC has evolved to meet today’s challenges

Under speculative circumstances, EHC began its China outsourcing "adventure." "We began with the 'low hanging fruit'," says Sgammato,"larger quantities, less sophistication, fewer steps, legacy products that would transition well to China." The success enabled the company to quickly return to profitability and inspired it to establish a separate division, EHC OEM. Leveraging these lessons learned combined with over 50 years of manufacturing experience, EHC OEM now serves as a supplier of end-to-end outsourced manufacturing solutions.

Why our experience can help your business

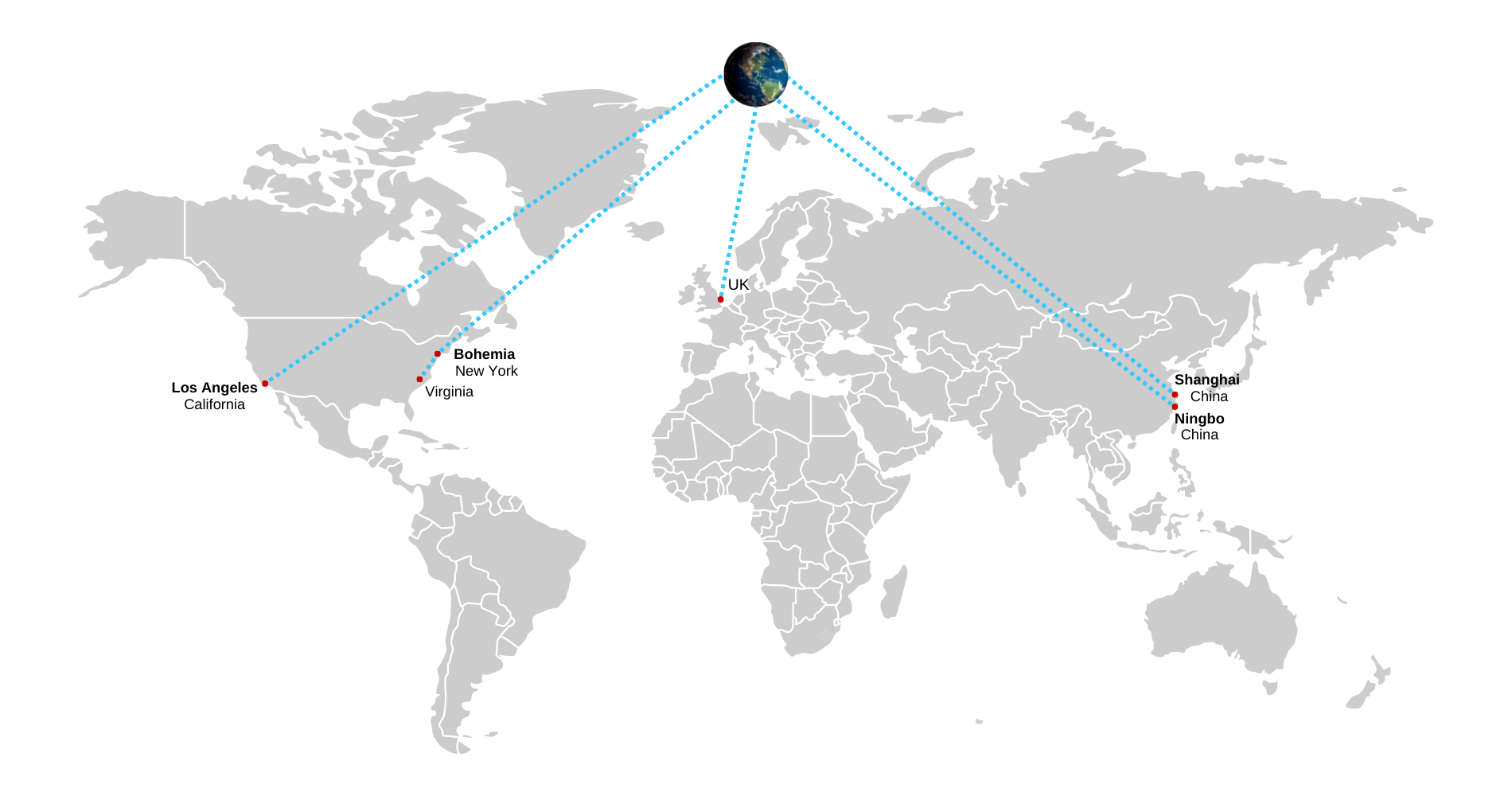

The past several years EHC has helped over thousands of small and mid-sized American and European OEMs with their contract manufacturing needs. EHC oversees the projects, handles the engineering and project management, as well as logistics.

Currently, there is a tendency to base outsourcing decisions solely on current performance rather than potential improvements offered by internal or external solutions. Even after years of belt tightening and incremental gains in efficiency, most manufacturers can still achieve 20-30 percent gains in direct labor productivity.

Manufacturers are faced with major challenges such as geographically diverse supply chains, reduced margins, tightening business regulations, and ever-increasing customer expectations. But they're also discovering that the extended supply chain represented by having their products manufactured offshore is not detrimental if they use the right approach. Part of that is managing the supply chain effectively, according to Sgammato, who counsels his customers that a manufacturer that outsources to China not only has to better manage its supply chain, but also customers’ expectations. "When you manufacture here, you have the ability to fulfill in a week or two. But with China or Vietnam your product is on a container ship for a month." Sgammato says the customer has to accept that the lead-time has jumped from two weeks to six and they in turn have to make adjustments in how they manage their supply chains.

Key points to remember when considering outsourcing

Successful offshore manufacturing outsourcing is based on the capabilities of a country's workers, and then on the products that are best sent offshore, not the other way around.

When outsourcing manufacturing to China, a common communication channel must exist that can be used and understood in all areas: engineering, production, operations, and supply chain.

OEMs that send redundant production duties overseas can expand their customer base because they are free to focus more of their attention on business, product R&D, and sales and marketing.

Our China offices serve as our hubs for source development and vendor qualification. They act as the liaisons to the factory and clarify all questions to and from the factory. They handle all stages of inspection prior to client approval, and arrange for shipping of finished products from China.

Areas where we excel include:

- Design and Engineering Support

- Logistics

- Precision Molding

- Die Casting & CNC Machining

- Small Part & Sub Assembly Manufacturing

For decades we have specialized in component manufacturing for the Aerospace industry, the Medical community, and the Industrial sectors. EHC's services also include the design and manufacturing of complex die cast and electro-mechanical assemblies. Call to learn how we can help you. 1-800-752-1680